Versions Compared

Key

- This line was added.

- This line was removed.

- Formatting was changed.

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

Overview |

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

|

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

Inventory Process Flow Diagram |

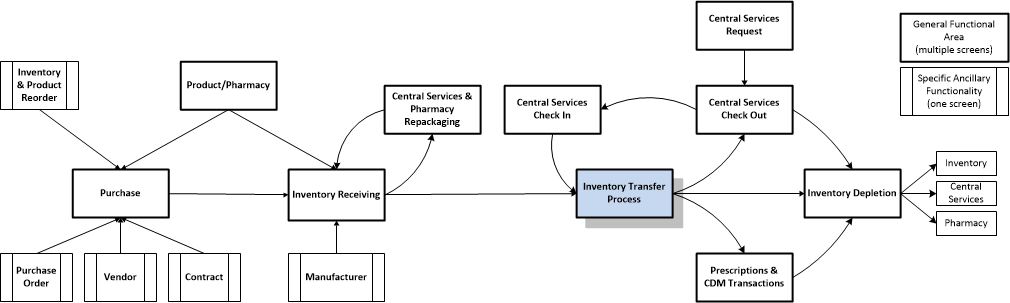

This flow diagram illustrates the process used to define products, vendors, and contracts; order, and receive, products into inventory; transfer, and check out, inventory among inventory areas; and finally, deplete, or dispose of, inventory.

Following, is a definition of the objects represented in the Inventory Process Flow Diagram above.

Purchase

The purchase of products is usually initiated with a Purchase Order. Products are also purchased through other means, such as: use of a credit card through the Vendor’s online store, or over the phone.

Before a purchase can be made, the product must be created in VetView.

A Purchase Order is a list of products to be purchased from a vendor. For each product to be ordered from the vendor, the purchase order defines: the order quantity; sales, stock, and order units; sales-to-stock, and stock-to-order ratios; vendor's catalog name, number, price.

Products must be purchased from a vendor that has been defined in VetView.

Contract

Products may be purchased from a vendor through a contract, which is a predefined agreement of pricing and terms.

Inventory order automation, based on the current inventory on hand, the minimum quantity, reorder quantity, and default vendor for each product.

The entry point for products in the hospital inventory as finished products to be sold, or raw goods to be repackaged. Bar-codes are assigned by the manufacturer, or they can be created from within VetView. Bar-codes scanning automates data entry for products as they enter the hospital inventory, or are transferred, or sold.

- Central Services & Pharmacy Repackaging

Inventory can exist as raw goods to be repackaged or assembled (as a compound, kit, or pack) to create a final product that will be used and sold.

- Manufacturer

When products are added to inventory, the manufacturer of the product can be identified. Along with the manufacturer, the inventory location, order unit, stock unit, sales-to-stock, and stock-to-order conversion ratios, expiration date, lot number, and controlled substance serial number, may be specified when inventory is received. These attributes make quantities of a product in inventory unique. Although they may be modified, VetView will default these attribute values based on historic inventory information - dynamically saving and updating these attributes as inventory is ordered and received.

Movement of products from one inventory area to another. The process starts with a request for products from a destination inventory area. The requested products are transferred by the source inventory area; then, received by the destination inventory area. Products that have been transferred, can be adjusted, or returned, after they have been received.

- Central Services Request

The 'Central Services' unit is usually responsible for sterilization, assembly, and tracking, packages of equipment, and expendable supplies, for procedures. The Central Services Request is advanced notice for a pack or kit.

- Central Services Check Out/In

Reusable inventory, such as instruments and equipment, is tracked through a check-out/check-in process. Inventory, not checked in, is removed from inventory through the Inventory Depletion process.

- Inventory Depletion

Products that are permanently removed from inventory can either be charged on a Client’s order, charged as ‘floor stock’ to a hospital unit; or, identified as waste, lost, or stolen. Items identified as lost or stolen can potentially be recovered back into inventory.

- Central Services Check Out

Reusable Inventory, such as instruments and equipment, is tracked through a check-out process which removes it from inventory, but holds it in a ‘checked-out’ state in anticipation of it being returned to inventory when it is checked in. Inventory that’s not checked in is ‘used’ and permanently removed from inventory through the Inventory Depletion process.

- Prescription & CDM Transactions

Pharmacy products may be removed from inventory through the prescription process, or as Control Drug Machine (CDM) withdrawal transactions.

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

Open Issues |

| Expand | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| |||||||||||||||||||||||||

|

| Insert excerpt | ||||||

|---|---|---|---|---|---|---|

|

| Info |

|---|

| This page may contain functionality not found in the current version of VetView. |

| Info | ||

|---|---|---|

| ||

Refer to the 'Inventory and Accounting Definitions' wiki page for definition of inventory terms, and for details about fields and controls. |

| Panel | ||

|---|---|---|

| ||

|